Our team of knowledgeable gearheads is prepared to join the constantly growing list of real-world uses for 3D printing. Eleven state-of-the-art models were gathered to operate side by side in our laboratory. We are able to assess each printer’s performance in handling fine details, flat surfaces, corners, overhang geometry, bridge across spans, articulated pieces, and more by using a carefully selected cadre of print models. We examine all possible support options and assess the challenges of constructing and operating the physical unit.

Table of Contents.

- No 1 Original prusa sl1

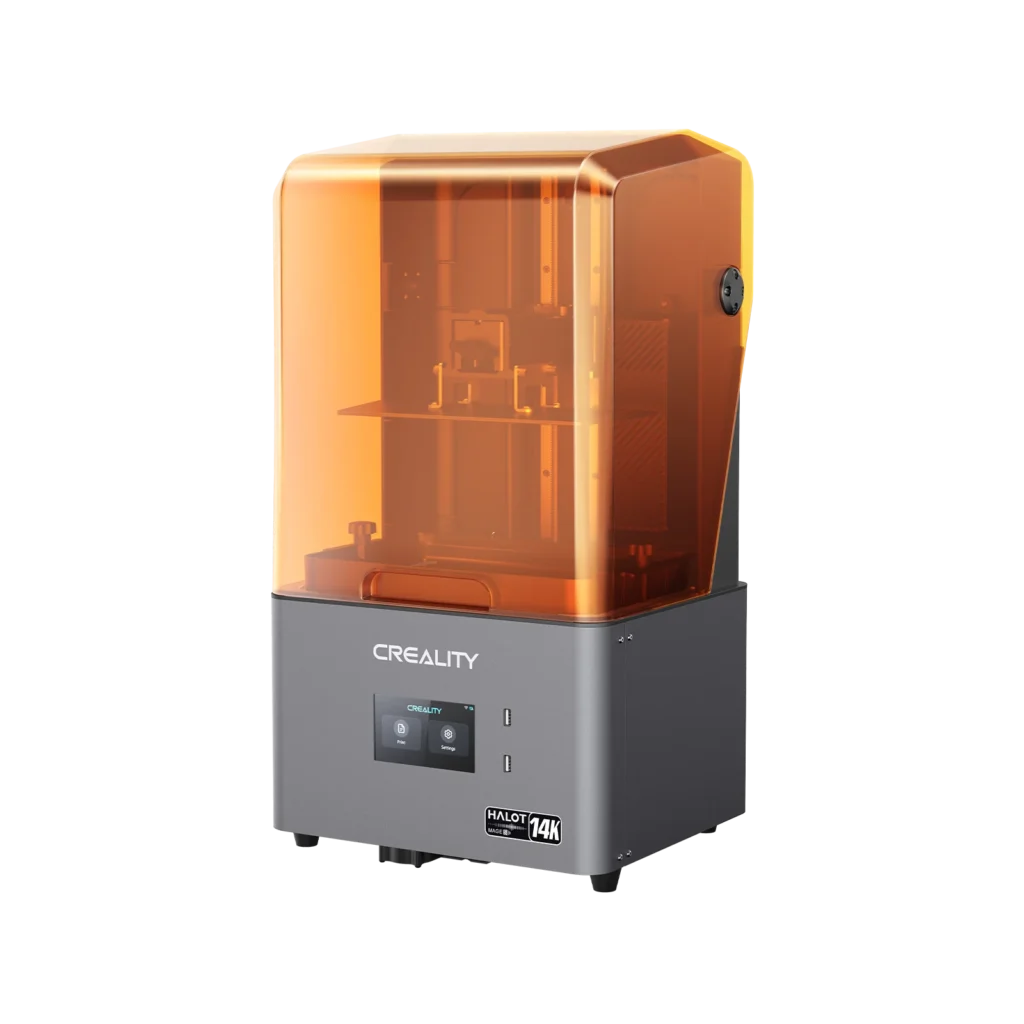

- No 2 Creality Halot-Mage S 14K

- No 3 FormLabs Form 4

Top 3 Best 3D Printers In 2025

No 1 Original prusa sl1

The Original PRUSA SL1 is easy to set up, and the device’s print quality far surpasses FFF 3D printers, even the Original PRUSA i3 MK3s. Although fused filament fabrication, or FFF, remains the most often used format, 3D printing technology has advanced rather quickly.

Stereolithography, or SLA as it is more often known, is a kind of 3D printing that employs liquid resin instead of solid filament. After curing the resin layer by layer using a UV light emitted from the print head, the surplus resin is removed and the print is allowed to dry.

There is a lot of room for mess, as you may guess, but the prints that are produced are usually amazing.

An MSLA 3D printer, which is a variation of SLA technology, is the SL1. It employs a high-resolution LCD that shows a mask instead of a print head that travels from one place to another. A UV LED panel then shines light through the mask to expose and cure the resin.

The print process is much quicker than printing at the same resolution on an FFF or conventional SLA printer since every layer is exposed simultaneously. As a result, it resembles a DLP printer method more. The Original Prusa SL1 is one of those devices that has an instant magnetic appeal. People are examining the slim black and orange box as soon as they enter the workshop.

The enormous transparent orange door that opens to expose the resin tank and construction plate looks great from an aesthetic standpoint. On the base is a large LCD touch screen that enables you to navigate settings quickly.

There’s nothing here that looks openly Open-Source, this feels like a proper commercial product. On the base is a large LCD touch screen that enables you to navigate settings quickly. There’s nothing here that looks openly Open-Source, this feels like a proper commercial product.

Pros

- Incredibly cheap for an SLA printer

- Outstanding print quality

- Open source resin compatibility

Cons

- Resin is always messy

- Steep learning Curve

- Can’t see print until it raises from the tank

No 2 Creality Halot-Mage S 14K

The HALOT-MAGE S 14K Resin 3D Printer is the evolution of the range, leaping in resolution from the 8K printer that impressed us so much earlier in the year. There are a few key differences beyond just the resolution between the HALOT-MAGE Pro and the HALOT-MAGE S, with this printer focusing more on high-quality sharp edges and resolution than the speed of the 8K version.

The printer itself is relatively large at 325 x 295 x 640 mm, though the footprint is small. The height means you need a bit of headspace to flip up the “MageArch” flip lid. The “soli” build features a metal base and vertical print platform, and the machine weighs 10.5 kg Inside, there’s a bolted prithere’sform measuring 223 x 126 mm, featuring a lever-carved design on the build plate, offering better adhesion. The Plus Motion system helps improve print quality and control.

The print area, slightly smaller than the 8K version, measures 218 x 123 x 230 mm, allowing decent-sized models. For model transfer, you can use a USB key, Ethernet, or wi-fi, and you can even remotely control the machine using Creality Cloud. At the heart of the machine is the 14K 10.1-inch LCD screen, protected by a cover with tanks on either side.

Like the 8K model, there is a smart air purifier, though not as advanced as the 8K version. It still helps minimize resin odour. To further enhance accuracy, the machine uses heavyweight linear rails and a rigid Z-axis, reducing wobbling so the outer surfaces of prints come out smoother.

There’s also a mighty closed-loop motor with fixed 1,300 Newton meters, enabling quick starts and stops with no vibration at low speeds and no loss of quality at high speeds, contributing to overall print quality.

Pros

- Solid build quality

- Excellent reliability

- Keeps things nice and simple

Cons

- No auto-fill resin tank

- Still requires plenty of maintenance

No 3 FormLabs Form 4

The powerful Form 3+ resin 3D printer’s capabilities and reputation are expanded upon by the Form 4. To improve speed and accuracy, the new machine switches from SLA (laser) to SLA (MSLA) technology. It is immediately noticeable how much faster the normal V5 materials are. Formlabs has established itself as the preferred device for companies in need of an affordable and dependable 3D printer for a variety of tasks, including mechanical, medical, and prototyping.

This is one of the most comprehensive and user-friendly solutions available due to the large assortment of specialty materials and the excellent environment that consists of a finishing station, wash and cure machines, and other equipment.

While the greatest 3D printers at the lower end of the market are excellent for hobbies, they sometimes lack the consistency and dependability needed for heavy professional usage. Form 3+ and Form 4 occupy a niche with few direct rivals; many professional-level machines cost tens of thousands of dollars. First and foremost, whether it’s a small product production run or a new version of a prototype, Form 4’s PreForm software and dashboard make the preparation and uploading process simple.

The variety of materials offers a solution for almost any intended end-use, from silicone, elastic, and biocompatible materials to general-purpose V5 materials that may be printed quickly.

The Form 4 impresses right away with some of the fastest, most precise, and most detailed prints we’ve seen from any 3D printer to date. In this review, we’ve concentrated on the most common and reasonably priced V5 materials to show what this printer can do. The biggest design difference for the Form 4 is the switch from Low Force Stereolithography LFS used by Form 3+ to Masked SLA MSLA technology.

Pros

- Incredibly fast print speeds

- Good range of materials

- High-quality prints

Cons

- Best to apply for support in PreForm

- Resin expensive

Best 3D printers: FAQs

What is a 3D printer?

In contrast to office-style printers, which print ink onto paper, 3D printers allow you to create digital models of real-world items composed of wood, metal, and plastic for prototyping, spare parts, and goods that are ready to go to market. Nowadays, FDM printers are available in a wide range of sizes and forms, making them ideal for bigger product fabrication and prototyping. A terrific investment for anybody wishing to design jewelry or make tabletop miniatures, resin-based (SLA, MSLA, and DLP) printers provide significantly more detail, usually at a smaller size.

3D printing is a means to create tangible items that is unlike any other approach we have seen, whether you are a hobbyist trying to get started in the field or your company depends on it. 3D printing is a simple method of producing goods using additive processes, which results in little to no waste. Furthermore, because almost anything can be 3D printed, the possibilities are virtually limitless.

What kind of materials does a 3D printer use to print?

A variety of materials are used by 3D printers for printing.

Because they are often inexpensive and simple to operate, entry-level FFF 3D printers continue to be the most popular. These filament printers, which employ polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), PETG, TPU, nylon, and polycarbonate, are good for prototype and general usage. Currently, PLA and ABS are the most widely used of these.

For complex modeling, a resin 3D printer or stereolithography (SLA) printer provides more quality and accuracy, but they are more expensive. The final model is produced by these printers using a photosensitive resin that is exposed layer by layer. Although it takes longer to set up and is a little messier, this allows you to print more intricate and detailed graphics.

In addition to plastics, some of the greatest 3D printers we’ve seen use metals and concrete. Few of these will be visible on a desktop. However, it’s a potential route to more sustainable and effective home construction and other major building projects.

What’s the difference between FFF vs FDM 3D printers?

While effectively employing the same printing process and using the same materials, there are some differences between a fused filament fabrication (FFF), fused deposition modeling (FDM) printer.

Firstly, FDM is a name trademarked by Stratasys – although other companies can use the name. But it’s not the only difference.

You’ll find variations in print quality. Working with more materials than FFF 3D printers, true industrial-grade FDM printers offer larger build platforms, fusing use layers closer together for a stronger bond.

On the other hand, this makes them more expensive to buy and run compared to FFF printers, which are popular especially among beginners.

Do 3D printers use a lot of electricity?

It depends on the size of your 3D printer, what materials are being used and how long you’re using the machine. In our experience, FDM printers use the least amount of power compared to other 3D printers.

What is the most profitable thing to make with a 3D printer?

There are a wide range of profitable items that can be made with a 3D printer. These range from personalized items such as phone cases an others, to replacements parts, prototypes, and teaching tools. Any of those areas, if marketed correctly, has the potential to be profitable.

Is 3D printing worth investing in?

Like other things, it depends on how and how frequently you plan to use your 3D printer. 3D printing is well worth the investment if you like modeling and printing, whether for personal or commercial usage. This is particularly true as the price of entry-level 3D printers continues to decline.